Valves play a key role in many systems and machines. But how do you choose the right valve products for your needs? Picking the wrong one can lead to problems and costly repairs.

The right valve suppliers can guide you to the best choice. In this blog, you will learn simple steps to make the right decision.

This guide is easy to follow and will help you understand what to look for when selecting valves. Let’s get started!

Understand Your Application

Each application has different needs for valve products. Think about what the valve will control, such as gas, liquid, or steam. Will it face high temperatures or pressures?

These severe service valves are designed for tough environments. You must also check the size and flow rate required. This helps avoid problems later.

Always match the valve’s features to your system. Write down the key requirements before talking to valve suppliers. This simple step can save time and effort.

Know the Valve Types

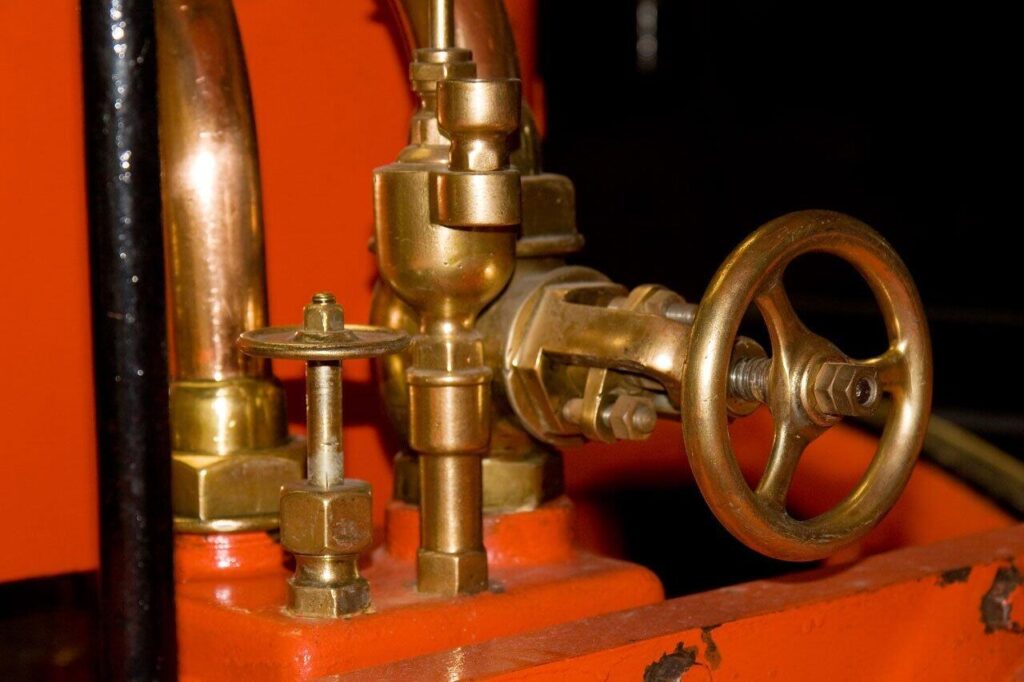

There are many types of valves for different tasks. Gate valves control flow by opening or closing fully. Ball valves are good for quick on-and-off actions.

Globe valves help regulate flow with precision. Butterfly valves are compact and lightweight for large systems. Research which type fits your job best.

If unsure, ask valve suppliers for advice. A good supplier can explain the pros and cons of each option. Knowing the types makes your choice easier.

Check the Material

Valves come in materials like metal, plastic, or a mix. Your choice depends on the substance flowing through the valve. For example, stainless steel works well for corrosive liquids.

Plastic is lightweight and resists certain chemicals. Some valve products are better for food or medical use. Ask your valve suppliers about material options for your needs.

Picking the right material ensures the valve lasts longer and works well. Never guess; always confirm with an expert.

Look at Maintenance Needs

Some valves need frequent checks or part replacements. Think about how often your system can afford downtime. Easy-to-maintain valves are best for busy systems.

These severe service valves often require extra care but last longer. Choose a design that fits your system’s upkeep schedule. Talk to valve suppliers about what maintenance is needed.

A little planning now can prevent big problems later. Remember, a valve that’s hard to maintain can cost more over time.

Compare Costs and Brands

Not all valves are priced the same. Compare brands and their features carefully. Cheaper valves might not last as long as quality ones.

A trusted valve supplier will explain why some options cost more. Think about long-term savings from a durable product. Ask if the supplier offers warranties or service support.

Valve products with good reviews are often a safer choice. Avoid rushing to buy; a little research can go a long way.

Learn How to Choose the Right Valve Products

Choosing the right valve products doesn’t have to be hard. Start by learning about your system’s needs and matching them to the valve. Always consult reliable valve suppliers for expert advice and support.

Check the material, maintenance, and cost before deciding. A well-chosen valve will save time and money in the long run.

Remember, careful planning ensures the best valve supply for your system. Use these tips to make confident choices and avoid mistakes.

Did you find this article helpful? If so, check out the rest of our site for more informative content.