CNC machining is changing the way we think about manufacturing. Have you ever wondered how toys, cars, or even planes are made? These objects often start their journey in a CNC machine shop, where clever technology allows for precise and quick production.

One of the most exciting developments in this field is automation. Automation means using technology to do tasks that used to require human hands.

Let’s dive deeper into how automation is revolutionizing CNC machining and why it’s a game-changer for the manufacturing industry.

Understanding CNC Machining

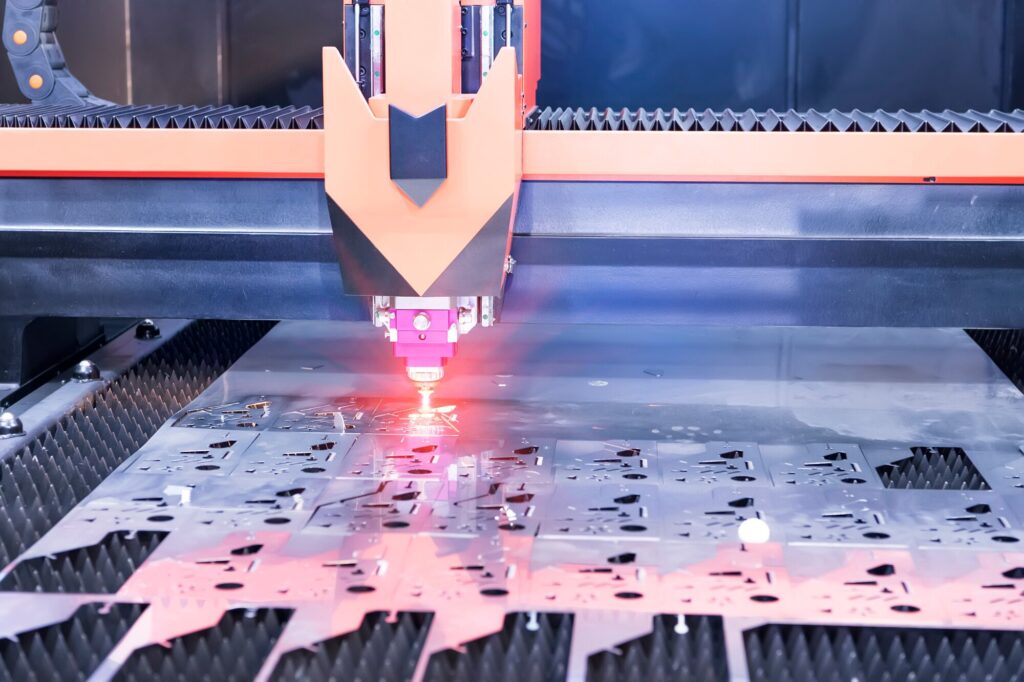

CNC machining stands for Computer Numerical Control machining. It’s a process that uses computers to control tools that cut and shape materials.

Imagine a giant robot arm that can move in many directions to create super-complex shapes and designs. This technology helps manufacturers produce parts that are more accurate and faster than traditional methods.

Automation in CNC Machining

Automation brings a whole new level of efficiency to CNC machining. By using advanced technology and robots, manufacturers can produce items continuously without taking breaks.

For instance, a CNC machine can operate all day and night, making the same parts over and over again. This constant operation leads to:

Increased Production

With fewer delays, different businesses can make more products in less time.

More Accuracy

Machines don’t get tired or make mistakes like humans do. They consistently deliver high-quality parts.

Cost Savings

Although the initial setup cost for automation can be high, in the long run, companies save money because they need fewer workers and experience less waste.

Reducing Human Error

One of the biggest challenges in manufacturing is human error. People can make mistakes, especially when they are tired or distracted. Imagine if a worker accidentally inputs the wrong measurement into a CNC machine. That could lead to unusable pieces or even safety hazards. However, automating the process significantly reduces human error. Robots and computers follow precise instructions to the letter.

When businesses rely on automated systems, the quality of their products improves. Companies that implement automation often see a decrease in errors. This means that parts made using CNC machining are not only faster to produce but also more reliable.

Impact on Job Roles

Some people worry that automation will take away jobs, but that’s not entirely accurate. While some tasks may be done by machines now, this shift allows human workers to focus on higher-level tasks.

As automation continues to grow in the CNC machining industry, workers may find themselves learning new skills. Training programs are being created to help workers move into jobs. These roles let them work with machines instead of being replaced by them.

The Future of CNC Machining

The future looks bright for CNC machining with automation paving the way. As technology advances, we can expect even more improvements in speed, accuracy, and efficiency. Innovative tools, like artificial intelligence, are already being integrated into CNC machines.

For those interested in stepping into this world, now is a great time to explore opportunities. If you want to learn more about how to start your journey in this field, find a CNC machine shop here that can offer guidance and support.

Embracing the Change With CNC Machining

Automation is not just a trend; it’s revolutionizing CNC machining in meaningful ways. By reducing human error, it’s setting the stage for a future where manufacturing is smarter and more efficient.

Embracing automation brings a new era to manufacturing. It’s an exciting time to be involved!

Need more ideas? Check out our other helpful articles on our website.